A constant exchange of information with the market, through our widespread sales network, allow s us to promptly know new trends and needs in the various geographic areas.

Accurate studies and designs enable us to create advanced products in terms of functionality, innovation and quality, complete with the required production and assembly equipment. This is possible thanks to a technical department consisting of 30 professionals who make use of the most up-to-date computer systems.

We have been focusing since 2019 on the internal training at all corporate levels, thanks to the recruitment of highly qualified professionals for the introduction of the LEAN philosophy and other innovative tools, whose heart is the creative laboratory Thinking Fapim: a workshop of ideas where we imagine the future of our company through the research and the verification of new technologies.

Laboratories

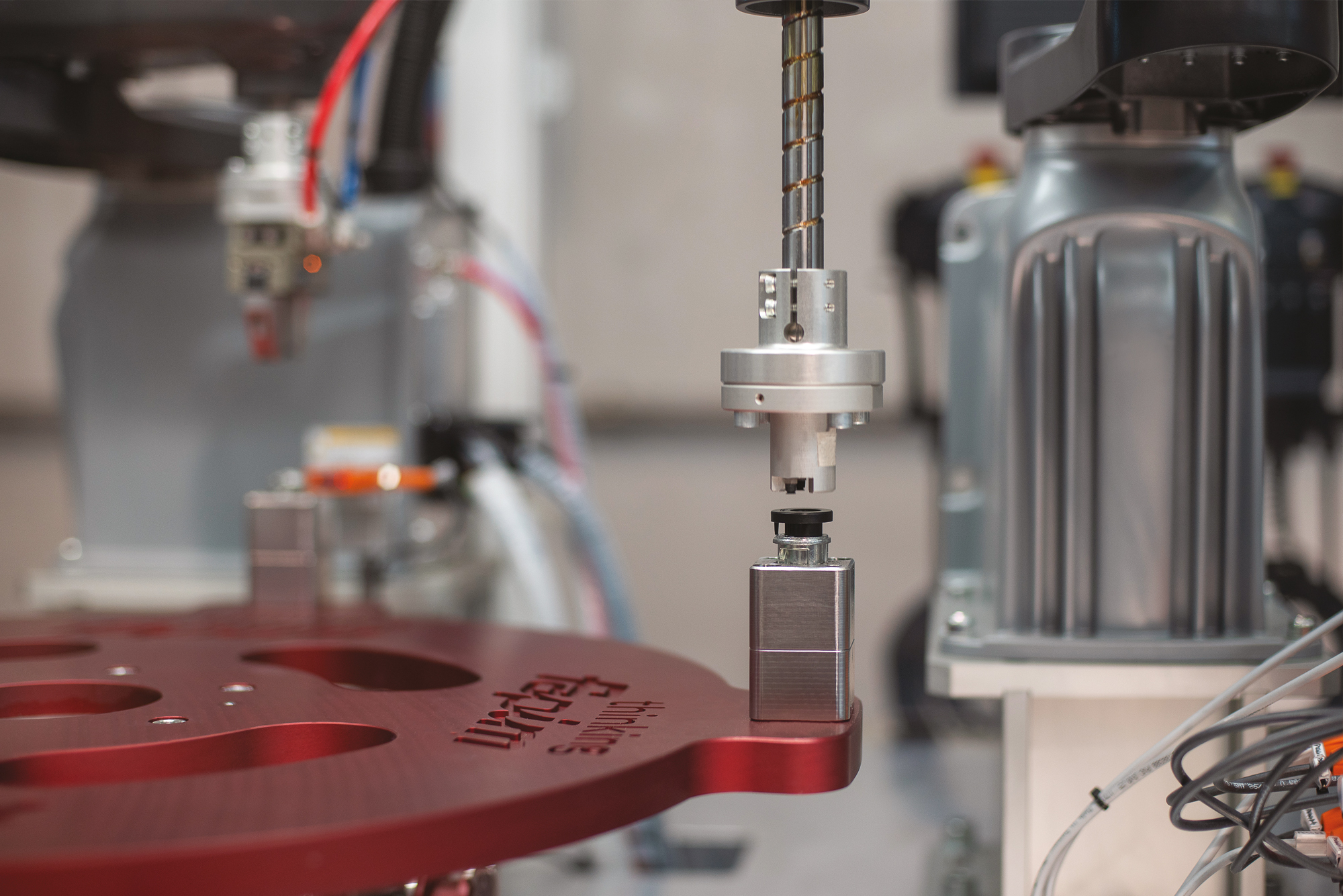

In the Fapim advanced laboratories we test the mechanical and chemical resistance of our products, carry out verifications and researches on new solutions and materials and production monitoring. Thanks to our equipment and experience, our laboratories have been accredited by the most prestigious Italian and international institutes therefore we are authorized to perform “witness” tests. The presence in our laboratory of testing equipment in compliance with the directives issued by the leading certification bodies, allows us to faithfully repeat the same rigorous tests of resistance and wear already passed to obtain the international certifications, this ensuring a constant high quality standard to our products.

A special team in the chemical laboratory takes care of the systematic monitoring of the anodizing plants and of the painting pre-treatment systems. The same team also provides for frequent verifications on the surface finishes to assess their resistance to atmospheric corrosion and mechanical abrasion (by accelerated corrosion in salt spray chamber), besides testing the corrosion resistance in the salt spray chamber.

Innovation and technology

Our production process, fully integrated and vertical, is one of the Fapim points of strength, that allowed to establish ourselves on the market as a guarantee of high quality and reliable products. Starting from high quality raw materials such as extruded aluminum, zinc or aluminum alloys, stainless steel and plastic material, the entire production is carried out in the two factories in Altopascio, thanks to a number of departments and progressive and linked processes up to the final packaging.

The high technological level that sets us apart is well represented by high automation and continuous research for material and technology improvement. Automation and continuous productivity improvement do also characterize final machining, assembly and packaging, up to management of the material in stock within the automatic warehouse.

Fapim Investments in people, products and production have always gone hand in hand since we are convinced that trained people, passionate about their work and ready for the challenges, represent the largest corporate value; this value is transferred to our products that for this reason are innovative, reliable and successful.

Design

Fapim has always combined the research of product design with an almost obsessive attention to details.

For this purpose we set up a special team that, according to the ergonomic and aesthetic characteristics of each product, makes the prototypes until the desired result is almost achieved. This team, which is supported by the most sophisticated computer programs, is made up of highly skilled and qualified professionals.